北海新宏恒达机械设备有限公司前身是北海市新宏鱼粉设备有限公司,拥有多年的设备研发、生产、安装和调试维护经验。其工程师团队拥有大量从业**过20年、经验丰富的工程师,公司在科研方面投入大量资源,获得国家创新基金奖励,获得**企业等荣誉证书。每年申请、获得国家**、新型实用**数项。其中在干燥机方面获得了多项国家**,使得在产品特别是干燥机、浓缩设备、除臭设备等性能*树一帜。

2) 浓缩完成后的液体被输送至干燥机(同鱼粉生产工艺流程第4步),与榨饼一起经过干燥机的加热脱水处理,后成为成品鱼粉。

After the concentration the liquid is transported to the Dryer (same as the fishmeal production process step 4), mixing with the presscake in the Dryer to dehydrate and finally to become the powder of fish meal.

BEIHAI XINHONG HENGDA MECHANICAL EQUIPMENT CO., LTD. is a company with more than 20 years of experience, specializing in the rendering industry, and is a professional manufacturer of processing equipment for fishmeal and fish oil, meat and bone meal, and poultry byproduct meal, etc. BEIHAI XINHONG HENGDA has developed and provided a series of various specifications and processing capacity of equipment to meet the different needs of customers. Besides, BEIHAI XINHONG HENGDA has over the years committed to improve the quality of equipment, whose products have been long at the forefront of the industry in terms of quality and performance.

我们真诚希望能够为新老客户创造效益,服务好所有的客户。我们诚挚欢迎各位新老客户与我们一起创造更美好的事业。

We sincerely hope to be able to create benefits for all our customers, good service to all customers. We sincerely welcome every customer to cooperate with us to create a better future.

北海新宏恒达机械设备有限公司是一家具有二十年经验、专业生产湿法肉骨粉成套设备、湿法鱼粉鱼油成套设备的公司。公司研发出一系列各种规格和处理能力的成套设备,满足不同客户的需求。同时,公司也可根据客户的具体需求特别订制。北海新宠恒达机械设备有限公司多年来致力于提升设备的品质,其生产的设备在质量及性能方面均处于行业**。

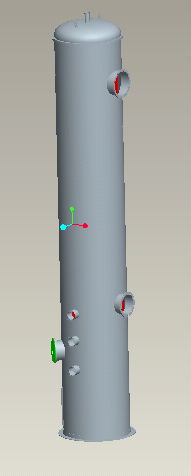

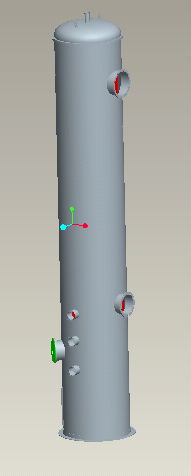

4. 蛋白水浓缩工艺Protein water concentration process

1) 离心机分离得到的②蛋白水液中含固体量一般情况约为5%,水分95%;送入浓缩设备进行浓缩,浓缩设备将大量水分蒸发掉,剩余的液体中含固量为50%,水分为50%;这样能够节约大量能源、节省蒸汽成本。(见浓缩设备工艺流程*3点。)

The amount of solids in the ②protein water is about 5%, the moisture is 95%. The protein water comes into the evaporator to concentrate as the machine evaporates a lot of water, and the remaining liquid contains 50% of solid, and 50% of moisture. In this way a huge energy and steam cost can be saved. (see Concentration process below).

-/gbacfae/-

http://xinhong779.cn.b2b168.com